The Essential Role of Con Rods in Diesel Engine Performance

In the realm of diesel engines, there are several critical components that play a significant role in the performance and reliability of the engine. Among these components, the con rod—short for connecting rod—stands out as an indispensable part of the engine assembly. Understanding the importance of con rods is crucial for anyone involved in the maintenance or manufacturing of diesel engines. This article explores the intricacies of the con rod, its functionality, the materials used, and how obtaining quality con rods from reliable suppliers can enhance engine performance while ensuring longevity.

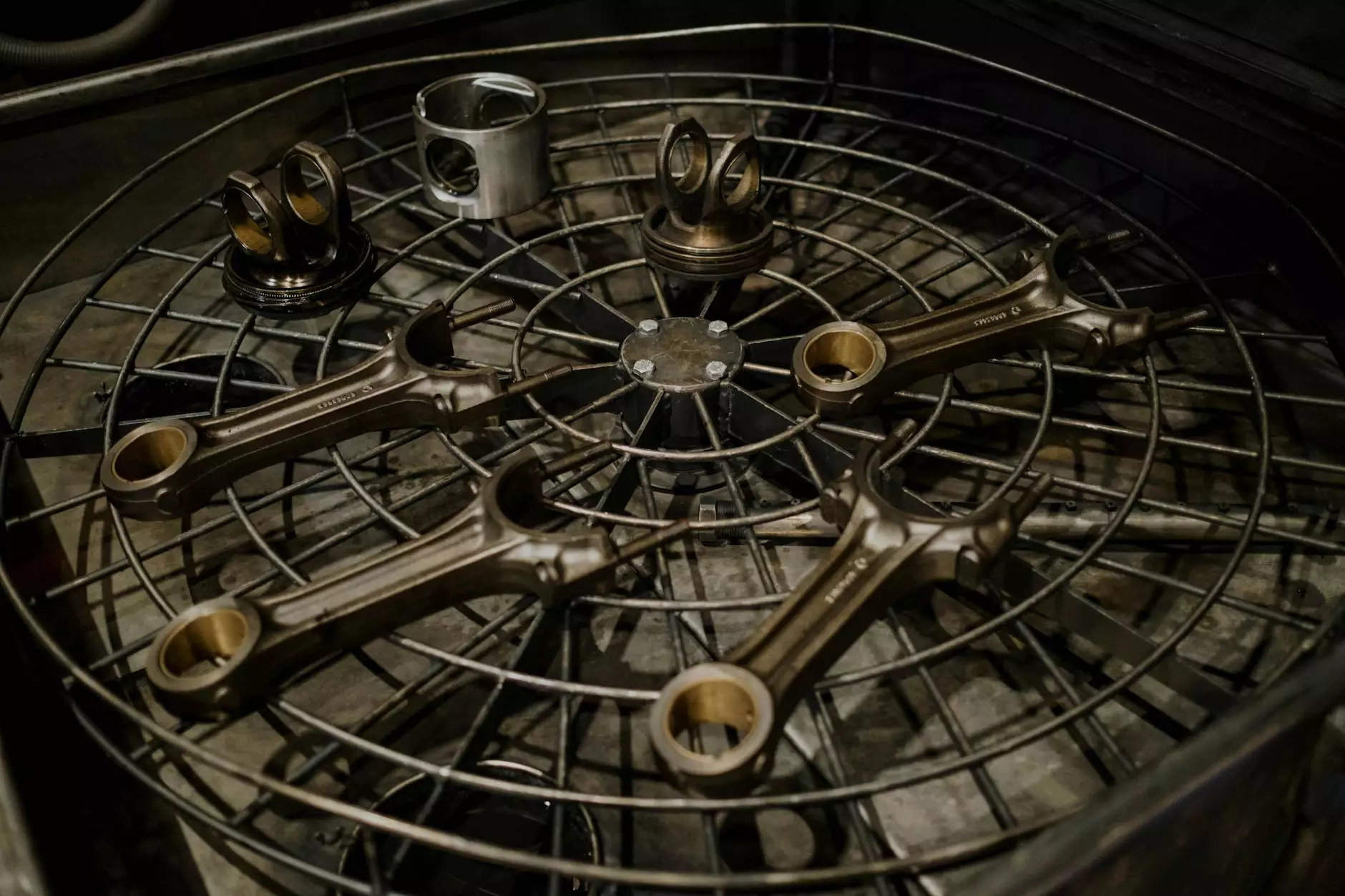

What is a Con Rod?

The connecting rod serves as a vital link between the engine's crankshaft and the pistons. Its primary function is to convert the linear motion of the piston into the rotary motion required to turn the crankshaft. This mechanical transformation is essential for the overall operation of internal combustion engines, particularly diesel engines known for their toughness and efficiency.

Understanding the Importance of Con Rods in Diesel Engines

In diesel engines, the following factors highlight the pivotal role of con rods:

- Power Transfer: The connecting rod effectively transfers power generated from combustion in the cylinder to the crankshaft, determining how effectively the engine can perform.

- Load Bearing: Con rods must withstand substantial loads and pressures. They play a crucial role in maintaining the integrity of the engine under varying loads and speeds.

- Stability and Longevity: A well-manufactured con rod contributes to engine stability, resulting in less wear over time and prolonging the engine's life.

Types of Con Rods Used in Diesel Engines

Various types of connecting rods are used in diesel engines, each designed to cater to specific engine requirements:

1. I-Beam Con Rods

The most commonly used design, I-Beam con rods are lightweight yet sturdy, making them ideal for high-performance engines where minimizing weight is critical without compromising strength.

2. H-Beam Con Rods

H-Beam con rods are known for their rigidity and strength. This design can handle more stress and is often employed in engines that operate at higher RPMs.

3. Forged Con Rods

These rods are made from a single piece of material, which enhances their strength and durability. Forged con rods are excellent for heavy-duty diesel engines that need to withstand intense operational pressures.

Materials Used in Manufacturing Con Rods

The choice of materials in con rod manufacturing greatly affects performance, weight, and longevity. Here are some common materials:

- Steel: Most common material offering a great balance between weight and strength.

- Aluminum: Used for lightweight applications, though not as durable as steel.

- Titanium: An advanced option providing excellent strength-to-weight ratio; however, it is more expensive.

The Manufacturing Process of Con Rods

Creating high-quality con rods involves several meticulous steps:

1. Material Selection

The manufacturing process begins with selecting the appropriate material, considering factors such as intended engine use, weight specifications, and strength requirements.

2. Forging and Machining

Once the material is selected, the rods are forged into shape, followed by precision machining to ensure they meet exact specifications. This step is crucial for ensuring that the con rods fit perfectly within the engine assembly.

3. Quality Control

The final step involves rigorous testing and quality assurance checks to ensure that every con rod meets the high standards required for optimal performance.

How Con Rod Quality Affects Performance

Investing in quality con rods can significantly influence the performance and reliability of diesel engines. Here’s how:

- Improved Engine Efficiency: Higher quality materials and manufacturing processes ensure better fit and function, which optimizes fuel efficiency.

- Enhanced Power Output: Stronger con rods can handle more power without breaking or deforming, leading to improved engine performance.

- Reduced Maintenance Costs: Durable con rods minimize the occurrence of engine failure, leading to lower repair costs over time.

Choosing the Right Supplier for Con Rods

Selecting a reputable supplier is essential for acquiring high-quality con rods. When assessing potential suppliers such as Client Diesel, consider the following factors:

1. Product Range

A good supplier will offer a variety of con rods to suit different engine types and specifications, ensuring you can find the right fit for your needs.

2. Quality Assurance

Look for suppliers who implement strict quality control processes and have certifications that demonstrate their commitment to excellence.

3. Customer Support

Reliable customer service can make a difference, especially when it comes to inquiries and support regarding specific products.

Conclusion

In conclusion, the con rod is a critical component of diesel engines that contributes to their efficiency, power output, and longevity. By understanding the importance of these components and choosing quality products from reputable suppliers like Client Diesel, businesses can ensure optimal engine performance and reliability. Investing in high-quality con rods not only enhances the immediate functionality of your equipment but also guards against costly downtimes and repairs in the future. For premium diesel engine parts, look no further than the offerings from Client Diesel, a leader in spare parts supply.

Explore more about our range of diesel engine parts and find the perfect con rod for your needs at Client Diesel.

https://client-diesel.com/en/products/con-rod